In the fast-paced food and beverage industry, efficiency, precision, and safety are paramount. One of the most significant contributors to streamlined operations is the use of food and beverage conveyors. These systems are engineered to handle a variety of products, from raw ingredients to packaged goods, optimizing production processes and ensuring quality at every stage.

Key Benefits of Food & Beverage Conveyors

1. Increased Efficiency

Food and beverage conveyors automate repetitive tasks, such as product transport, sorting, and packaging. This reduces manual labor, accelerates production timelines, and ensures a consistent flow of materials throughout the facility.

2. Enhanced Product Safety

Conveyors designed for the food and beverage industry are built with food-grade materials that meet strict hygiene standards. Features like smooth surfaces, easy-to-clean belts, and antimicrobial coatings prevent contamination and uphold product safety.

3. Versatility for Diverse Applications

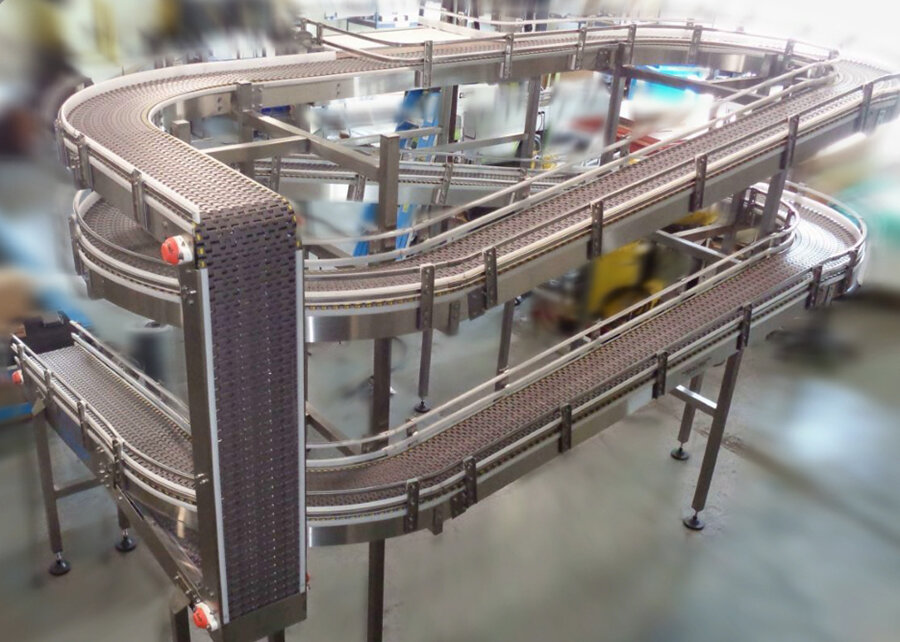

Whether you’re processing fresh produce, baking goods, or bottling beverages, conveyors can be customized to suit specific operational needs. Adjustable speed controls, modular designs, and specialized configurations ensure seamless integration into any production line.

4. Improved Quality Control

Advanced conveyor systems incorporate technology like sensors, vision systems, and weighing scales to identify defective items, maintain consistent portion sizes, and ensure uniformity in packaging. This minimizes waste and enhances product quality.

5. Scalability and Flexibility

As your business grows, so can your conveyor system. Modular designs allow for easy expansion, while flexible configurations adapt to new product lines or changes in production demands.

Applications in the Food & Beverage Industry

- Sorting and Grading: Automates the separation of products by size, weight, or quality.

- Packaging and Labeling: Streamlines processes for boxing, sealing, and applying labels.

- Cooling and Freezing: Utilizes temperature-controlled conveyors for frozen or chilled goods.

- Inspection: Ensures compliance with safety and quality standards through automated scanning and sorting.

Why Choose Trans Automation Technologies?

At Trans Automation Technologies, we specialize in designing and delivering custom food and beverage conveyor solutions tailored to your specific production needs. Our systems are engineered for durability, efficiency, and compliance with industry standards. From consultation to installation, our team is committed to helping you achieve optimal productivity and operational excellence.

Ready to Transform Your Production Line?

Investing in the right conveyor system can revolutionize your production processes and set your business apart in the competitive food and beverage market. Contact Trans Automation Technologies today to learn how our innovative conveyor solutions can enhance your operations.